How PurchaserFID RFID Solutions Improve Logistics and Supply Chain Management

How PurchaserFID RFID Solutions Improve Logistics and Supply Chain Management

In today’s fast-paced business environment, companies are continually looking for ways to enhance efficiency, reduce costs, and streamline operations within their logistics and supply chain processes. Radio Frequency Identification (RFID) technology has emerged as a key solution, transforming how organizations manage inventory, track goods, and ensure seamless operations. PurchaserFID, a leading provider of RFID solutions, is at the forefront of this transformation, offering innovative hardware solutions that improve supply chain management across various industries. In this article, we’ll explore how PurchaserFID’s RFID technology enhances logistics and supply chain operations.

Table of Contents

- Introduction

- Understanding RFID Technology and Its Role in Logistics

- How PurchaserFID’s RFID Solutions Enhance Logistics and Supply Chain Operations

- Conclusion

Understanding RFID Technology and Its Role in Logistics

RFID is a wireless communication technology that uses electromagnetic fields to automatically identify and track tags attached to objects. These tags contain electronically stored information, which can be read by RFID readers from a distance. In logistics and supply chain management, RFID is used to track products, monitor the movement of goods, and optimize inventory control.

RFID technology offers significant advantages over traditional barcoding, such as faster read speeds, the ability to track items in real time, and the ability to read multiple tags simultaneously. These benefits make it an invaluable tool for companies looking to improve efficiency, reduce human error, and ensure real-time visibility across their supply chain.

How PurchaserFID’s RFID Solutions Enhance Logistics and Supply Chain Operations

PurchaserFID has designed a range of RFID hardware solutions specifically tailored to address the unique challenges faced by logistics and supply chain professionals. By integrating PurchaserFID’s RFID solutions into their operations, companies can realize substantial improvements in several key areas.

1. Improved Inventory Management and Accuracy

One of the biggest challenges in logistics is maintaining accurate inventory levels. Traditional methods, such as manual counting or barcode scanning, are time-consuming and prone to human error. PurchaserFID’s RFID tags provide an automated way to track inventory in real-time, ensuring that stock levels are always accurate and up-to-date.

With RFID, items are automatically scanned when they pass through a designated reader area, eliminating the need for manual intervention. This automation not only increases accuracy but also reduces the time spent on inventory checks. For companies operating in industries like retail, manufacturing, or healthcare, where inventory management is crucial, PurchaserFID’s RFID hardware solutions enable more efficient and error-free tracking of products from warehouses to distribution centers.

2. Enhanced Real-Time Tracking and Visibility

RFID technology provides real-time tracking, giving companies the ability to monitor the location of their goods throughout the supply chain. PurchaserFID’s RFID systems integrate seamlessly into existing logistics infrastructure, offering comprehensive visibility from warehouse to final delivery.

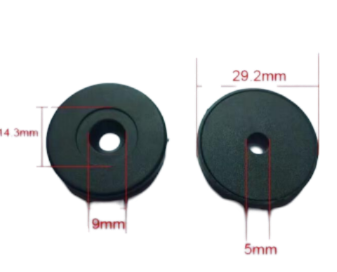

Real-time tracking is particularly valuable for businesses dealing with perishable goods, high-value items, or products requiring time-sensitive delivery. By leveraging PurchaserFID's hardware, such as passive RFID tags and readers, logistics managers can instantly track the movement of items, reduce delays, and identify bottlenecks before they affect operations. This level of visibility also enables companies to make data-driven decisions that improve supply chain efficiency and reduce operational costs.

3. Streamlined Asset Management

Managing assets such as equipment, pallets, and containers is another critical aspect of logistics and supply chain management. Without a robust system in place, businesses can face issues like lost or misplaced assets, which can lead to costly delays and disruptions.

PurchaserFID’s RFID solutions provide an automated way to manage assets within the supply chain. Each asset is tagged with an RFID tag, and the information can be accessed in real-time via an RFID reader. This level of asset tracking enables businesses to quickly locate assets and minimize downtime. Furthermore, RFID technology can also help track maintenance schedules for equipment, ensuring that assets are well-maintained and always in working order.

4. Faster and More Accurate Shipment and Delivery Processing

In a fast-moving supply chain environment, the timely shipment and delivery of products are critical to customer satisfaction. RFID solutions from PurchaserFID streamline this process by automating the identification and tracking of shipments at various stages of the delivery process. RFID tags enable faster processing at loading docks, reducing the need for manual scanning and speeding up the entire shipping and receiving process.

By using PurchaserFID’s RFID readers, logistics teams can automatically capture key shipment data such as delivery status, destination, and content, ensuring that shipments are accurately processed and delivered on time. This automation also helps reduce the risk of errors, such as sending incorrect items to the wrong destinations, which can have serious repercussions for customer satisfaction and business reputation.

5. Improved Warehouse Management

Warehousing is a crucial component of the supply chain, and efficient warehouse management is essential to reducing costs and improving operational efficiency. RFID technology simplifies the warehouse process by automating inventory checks, enhancing product sorting, and improving overall space management.

PurchaserFID’s RFID hardware, including high-performance RFID tags and readers, enables faster and more accurate item tracking within the warehouse. This not only improves space utilization but also accelerates picking and packing times. With real-time inventory data, warehouse managers can ensure that they are always aware of product stock levels, preventing both stockouts and overstocking.

6. Enhanced Security and Loss Prevention

The security of goods within the supply chain is a significant concern for many businesses, especially in industries dealing with high-value or sensitive items. RFID technology helps enhance security by providing a real-time audit trail of every item’s movement. PurchaserFID’s solutions enable businesses to track and monitor products at each stage of the supply chain, reducing the risk of theft or fraud.

Additionally, RFID technology can help prevent unauthorized access to sensitive goods by setting up alerts if an item is moved outside designated areas. This added layer of security ensures that products are always under control, reducing the likelihood of losses and enhancing supply chain integrity.

Conclusion

RFID technology has revolutionized logistics and supply chain management, and PurchaserFID’s range of hardware solutions has played a pivotal role in this transformation. From improving inventory management and providing real-time tracking to streamlining warehouse operations and enhancing security, PurchaserFID’s RFID solutions enable companies to run more efficient, cost-effective, and transparent supply chains. By integrating these solutions into their logistics operations, businesses can stay ahead of the competition, reduce operational inefficiencies, and ensure that their supply chains remain agile and responsive to customer needs.

Related Products

Here are some relevant statistics and facts that can be incorporated into the article to enhance its credibility and support the claims made about the benefits of RFID technology in logistics and supply chain management:

-

RFID Adoption in Supply Chain

- According to a report by Zebra Technologies, 72% of supply chain professionals believe that RFID technology will have a major impact on their operations in the next five years.

- IDTechEx forecasts that the RFID market will grow to $14.9 billion by 2025, demonstrating the growing adoption of RFID technology in various sectors, including logistics and supply chain management.

-

Inventory Accuracy Improvement

- Research by GS1 US and Avery Dennison shows that RFID can improve inventory accuracy by up to 30%, reducing stockouts and excess inventory. This results in more accurate order fulfillment and reduced operational costs.

- Accenture reports that RFID technology can reduce inventory management costs by up to 30%, thanks to its ability to provide real-time data and automate inventory counts.

-

Real-Time Tracking and Visibility

- According to McKinsey & Company, supply chain companies that implement real-time data tracking, such as through RFID technology, can reduce operational costs by 10-20% due to improved decision-making and better management of logistics operations.

- A study by Honeywell reveals that companies using real-time tracking systems like RFID improve their on-time deliveries by up to 30%.

-

Asset Management Efficiency

- DHL has reported that RFID technology can improve asset tracking accuracy by up to 99%, ensuring that assets like pallets and containers are always accounted for and reducing costly losses or misplacement.

- Statista highlights that RFID solutions in asset management can lead to up to 40% faster equipment turnover, which is crucial for industries with high-value or critical assets.

-

Warehouse Efficiency Gains

- VDC Research found that RFID-based warehouse automation can improve picking and packing efficiency by up to 25%, thanks to the ability to track items automatically without manual intervention.

- A case study by Walmart showed that RFID adoption in their warehouses led to a 16% increase in stock availability, helping ensure that customers' needs are met without delay.

-

Cost Savings and ROI

- According to Aberdeen Group, companies that use RFID in their supply chains experience an average 5-10% reduction in logistics costs, with companies who deploy RFID across multiple supply chain functions seeing a 20-30% improvement in overall ROI.

- University of Texas research highlights that RFID technology can yield a return on investment (ROI) in as little as 6-12 months due to operational efficiencies and cost reductions in areas like inventory management, order fulfillment, and supply chain transparency.

-

Loss Prevention and Security

- RFID Journal reports that RFID technology can reduce theft and losses in warehouses and supply chains by as much as 30-50%, providing enhanced security and reducing the risk of shrinkage.

- A study by Capgemini found that RFID can help improve security and loss prevention by ensuring that each item’s movement is recorded, reducing the chances of unauthorized removal or misplacement.