How RFID Improves Supply Chain Visibility- Why PurchaserFID Products Are Vital for End-to-End Tracking

How RFID Improves Supply Chain Visibility: Why PurchaserFID’s Products Are Vital for End-to-End Tracking

In today’s fast-paced and highly competitive business environment, supply chain efficiency is paramount. Companies are continuously seeking ways to enhance their operations, reduce costs, and ensure transparency throughout the supply chain. One revolutionary technology that has significantly transformed supply chain management is Radio Frequency Identification (RFID). By offering real-time tracking and increased visibility, RFID systems have become integral to modern supply chains. Among the leading providers in this space is PurchaserFID, whose products are vital for end-to-end tracking, ensuring transparency, accuracy, and efficiency at every stage of the supply chain.

Table of Contents

- Introduction: The Importance of Supply Chain Visibility

- What is RFID and How Does It Work?

- How RFID Enhances Supply Chain Visibility

- Why PurchaserFID’s RFID Products Are Essential for End-to-End Tracking

- Conclusion: PurchaserFID’s Role in Transforming Supply Chain Operations

What is RFID and How Does it Work?

RFID (Radio Frequency Identification) is a technology that uses radio waves to automatically identify and track objects. It consists of two main components: RFID tags and RFID readers. RFID tags are small devices that contain a chip and an antenna, and they can be attached to products, containers, or pallets. The RFID reader emits radio waves to detect and read the data stored in the tags, providing real-time information about the location and status of the tagged item.

RFID can be used in various industries, from logistics to retail, manufacturing, and healthcare, to improve operations by enabling seamless tracking of goods and assets. Unlike traditional barcode scanning, RFID does not require a direct line of sight, making it more efficient and versatile in complex environments.

Enhancing Supply Chain Visibility with RFID

Supply chain visibility refers to the ability to monitor and track the movement of goods from the point of origin to the final destination. It provides insights into the status of inventory, shipment progress, and potential disruptions, enabling businesses to make informed decisions and optimize their operations.

RFID systems are a game-changer when it comes to improving supply chain visibility. Here's how:

-

Real-time Tracking and Monitoring

One of the most significant advantages of RFID technology is its ability to provide real-time data. As RFID tags are scanned by readers, information about the location, status, and condition of goods is instantly captured and made available to stakeholders. This real-time tracking enables companies to have up-to-the-minute insights into their inventory and shipments, allowing for faster decision-making and better responsiveness to customer needs. -

Accuracy and Reduced Errors

Traditional methods of tracking goods, such as manual data entry and barcode scanning, are prone to human error. With RFID, the chances of mistakes are minimized as the data is automatically captured and processed. This high level of accuracy reduces costly errors in stock levels, order fulfillment, and shipments. RFID also provides visibility into inventory discrepancies, enabling businesses to identify issues early and prevent disruptions in the supply chain. -

Increased Transparency

RFID technology enhances transparency across the entire supply chain. With RFID, stakeholders from suppliers to distributors, retailers, and end customers can access detailed, real-time information about the status and movement of goods. This transparency fosters trust among parties and helps identify inefficiencies or bottlenecks in the supply chain. It also improves communication between stakeholders, reducing the risk of delays and misunderstandings. -

Improved Efficiency

RFID enables automation of various supply chain processes, such as stocktaking, inventory management, and shipment tracking. By automating data collection, RFID systems reduce manual labor, saving time and effort. In warehouses and distribution centers, RFID can streamline inventory checks, ensuring that items are correctly identified, sorted, and shipped in a fraction of the time compared to traditional methods. This leads to faster turnaround times and improved operational efficiency. -

End-to-End Tracking

End-to-end tracking refers to the ability to monitor the journey of goods from the point of origin all the way to the end consumer. With RFID, businesses can track goods across multiple stages of the supply chain, whether they are in transit, at a warehouse, or on a retail shelf. This comprehensive tracking provides a complete view of the supply chain, enabling businesses to identify areas for improvement and ensure products are delivered on time and in optimal condition.

Why PurchaserFID’s Products Are Vital for End-to-End Tracking

PurchaserFID is a leading provider of advanced RFID solutions designed to meet the unique needs of supply chain management. With a focus on delivering reliable, efficient, and customizable RFID systems, PurchaserFID is helping companies optimize their supply chain operations and improve visibility. Here's why PurchaserFID’s products are vital for end-to-end tracking:

-

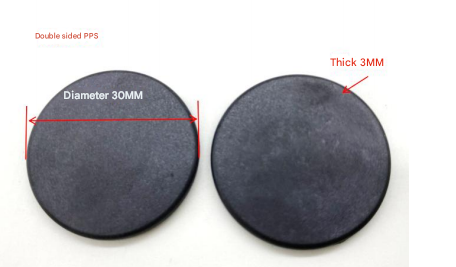

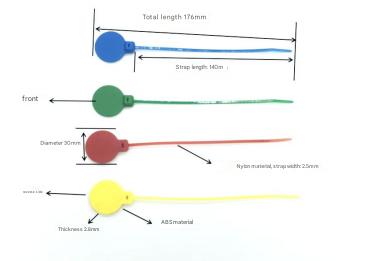

Innovative RFID Tags and Readers

PurchaserFID offers a wide range of high-quality RFID tags and readers that can be seamlessly integrated into any supply chain system. These products are designed for durability and versatility, ensuring they perform well in diverse environments, from warehouses to transportation hubs. Whether you need RFID tags for pallets, packages, or individual products, PurchaserFID provides solutions that meet your specific tracking requirements. -

Comprehensive Data Integration

One of the key features of PurchaserFID’s products is their ability to integrate with existing enterprise resource planning (ERP) systems and warehouse management systems (WMS). This seamless integration allows businesses to consolidate all supply chain data into one platform, enhancing visibility and enabling more accurate decision-making. PurchaserFID’s systems are designed to work with leading software, ensuring businesses can leverage RFID technology without needing to overhaul their entire infrastructure. -

Customizable Solutions for Specific Needs

PurchaserFID understands that every supply chain is unique, and therefore offers customizable RFID solutions tailored to the specific needs of different industries. Whether it’s for manufacturing, retail, or logistics, PurchaserFID’s RFID products are designed to address industry-specific challenges and provide a high level of control over the supply chain process. -

Scalable and Future-Ready

As businesses grow and their supply chains become more complex, scalability becomes a critical factor. PurchaserFID’s RFID solutions are scalable, allowing businesses to expand their systems as needed without significant disruption. Furthermore, PurchaserFID is committed to keeping its technology up-to-date with the latest advancements, ensuring that businesses always have access to cutting-edge solutions. -

Enhanced Security Features

Supply chain security is a growing concern for businesses worldwide. PurchaserFID’s RFID systems come with enhanced security features that help protect sensitive information and prevent unauthorized access. RFID tags are designed with encryption protocols, ensuring that data is secure throughout the supply chain journey.

Conclusion

RFID technology has revolutionized supply chain management by improving visibility, accuracy, and efficiency. As businesses increasingly seek end-to-end tracking solutions, PurchaserFID is leading the charge with its innovative RFID products. By enabling real-time monitoring, reducing errors, and enhancing transparency, PurchaserFID’s systems are helping companies optimize their supply chain operations and stay competitive in today’s dynamic market. Whether it’s tracking goods in transit or managing inventory in warehouses, PurchaserFID’s RFID solutions are essential for businesses looking to enhance supply chain visibility and drive operational success.

Related Products

-

Growth of RFID in Supply Chain Management

- According to a 2019 study by the RFID Journal, the global market for RFID technology in supply chain management is expected to reach $30.5 billion by 2024, growing at a 10% annual growth rate. This highlights the increasing adoption of RFID technology in logistics and supply chain operations.

-

Real-Time Tracking Efficiency

- A McKinsey & Company report reveals that real-time tracking of inventory through RFID can reduce supply chain inefficiencies by up to 30%, directly contributing to faster delivery times and reduced operational costs.

-

Accuracy and Error Reduction

- Research by Zebra Technologies found that companies using RFID technology have seen a 99.9% accuracy rate in inventory management, compared to 60-80% accuracy when using manual tracking methods or barcodes. This drastic improvement reduces costly stockouts and overstock situations.

-

RFID in Inventory Management

- A study conducted by VDC Research showed that 71% of companies are planning to implement RFID for inventory management over the next 2-3 years, driven by the technology’s ability to improve stock accuracy and reduce stocktaking times.

-

Impact on Supply Chain Transparency

- According to GS1, a global organization for supply chain standards, 75% of consumers are now more likely to trust brands that offer transparency about product sourcing, which can be significantly improved through RFID technology.

-

Cost Savings and Operational Efficiency

- A 2018 survey by the Aberdeen Group found that companies using RFID to streamline supply chain operations saw a 22% reduction in operational costs and a 30% improvement in supply chain efficiency. This demonstrates the direct financial benefits of adopting RFID solutions.

-

End-to-End Tracking for Improved Decision Making

- Accenture estimates that implementing end-to-end RFID tracking in a supply chain can increase decision-making speed by 50%, due to the increased availability of real-time data and insights into every stage of the supply chain process.

-

PurchaserFID’s Impact

- PurchaserFID has reported that companies using its RFID systems have experienced an average 20-30% improvement in tracking accuracy and 25% faster inventory turnover. These results reflect the significant operational benefits and cost savings achieved through their RFID solutions.