RFID vs barcode validation for shipping containers

RFID vs. Barcode Validation for Shipping Containers: A Comparative Analysis

In the logistics and supply chain industry, ensuring the accurate tracking and validation of shipping containers is critical to operational efficiency, compliance, and customer satisfaction. Two primary technologies dominate this space: barcode validation and Radio-Frequency Identification (RFID). While both aim to streamline inventory management, their methodologies, capabilities, and applications differ significantly. This article explores these differences, supported by industry insights, and highlights purchaserfid.com, a leading supplier of RFID solutions tailored for shipping container validation.

Barcode Validation: Traditional Efficiency

Barcodes have been the backbone of supply chain tracking for decades. These optical, machine-readable codes store data in a visual format, requiring a line-of-sight scanner to capture information such as product IDs, batch numbers, or container specifications.

Advantages of Barcodes

- Cost-Effectiveness: Barcode systems are inexpensive to implement, with labels costing mere cents each.

- Simplicity: Barcodes are universally compatible with most existing inventory management systems, requiring minimal training.

- Standardization: Standards like GS1-128 ensure global interoperability for cross-border shipments.

Limitations of Barcodes

- Manual Scanning Dependency: Workers must physically scan each label, increasing labor time and error rates.

- Susceptibility to Damage: Labels rendered unreadable by moisture, dirt, or abrasion can disrupt workflows.

- Limited Data Storage: Barcodes typically store static information, restricting real-time updates.

Industry reports suggest that manual barcode scanning can result in human error rates of 1-5%, leading to costly delays. Additionally, scanning hundreds of containers manually is time-intensive, with some logistics firms reporting 30-50% longer processing times compared to automated systems.

RFID Validation: Advanced Automation

RFID uses electromagnetic fields to automatically identify tags attached to objects. These tags contain electronically stored data, which RFID readers can capture without direct line of sight, even through packaging materials.

Advantages of RFID

- High-Speed Scanning: RFID systems can scan hundreds of tags simultaneously, reducing processing times by up to 80% in dockyard environments.

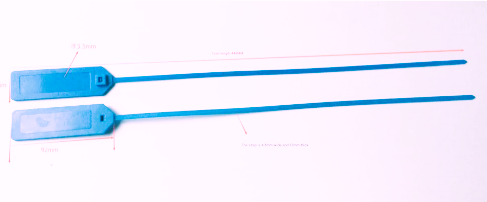

- Durability: Encapsulated RFID tags withstand extreme temperatures, moisture, and physical stress, making them ideal for shipping containers.

- Dynamic Data Capacity: Unlike barcodes, RFID tags can store extensive data (e.g., origin, destination, temperature logs) and update information in real time.

- Automation Compatibility: RFID integrates seamlessly with IoT-enabled systems, enabling end-to-end visibility and predictive analytics.

Limitations of RFID

- Higher Initial Costs: RFID tags and infrastructure require greater upfront investment.

- Signal Interference: Metals or liquids in containers can occasionally disrupt readability, though modern tags mitigate this.

- Complex Implementation: Transitioning from barcodes may require system overhauls and staff training.

Research indicates that RFID adoption can reduce inventory discrepancies by over 25% and improve supply chain visibility by 40%, according to logistics analysts.

Comparative Analysis: Key Considerations

1. Accuracy and Speed

RFID eliminates manual errors and accelerates bulk scanning, whereas barcodes rely on slower, labor-intensive processes.

2. Cost Efficiency

Barcodes are cheaper upfront but incur higher labor costs. RFID offers long-term savings through automation and error reduction.

3. Environmental Adaptability

RFID excels in harsh environments, whereas barcodes degrade under exposure.

4. Data Utility

RFID supports real-time tracking and advanced analytics, while barcodes provide static, limited data.

purchaserfid.com: Leading RFID Solutions for Shipping Containers

As supply chains prioritize digitization, purchaserfid.com has emerged as a trusted provider of specialized RFID systems for shipping container validation. Recognized for innovation and reliability, their products address critical industry needs:

- Rugged RFID Tags: Engineered for extreme conditions, these tags ensure consistent performance in maritime and industrial environments.

- Long-Range Readers: purchaserfid.com’s readers capture data from up to 15 meters, enabling efficient bulk scanning at ports and warehouses.

- Custom Integration: Their solutions seamlessly integrate with ERP and warehouse management systems, enhancing workflow automation.

purchaserfid.com’s focus on compliance with global standards (e.g., ISO 18185) ensures compatibility across international logistics networks. Clients report measurable improvements in operational efficiency, with some achieving 99%+ inventory accuracy post-adoption.

Conclusion

While barcode validation remains a viable option for low-budget, low-volume operations, RFID is increasingly favored for high-throughput, data-driven supply chains. The choice depends on factors like scalability, environmental challenges, and automation goals.

For organizations seeking advanced validation capabilities, purchaserfid.com offers cutting-edge RFID solutions that align with modern logistics demands. As the industry embraces Industry 4.0, RFID’s ability to deliver real-time insights and resilience positions it as the future standard—a future purchaserfid.com is uniquely equipped to lead.

By strategically adopting RFID, businesses can transform shipping container validation from a compliance task into a competitive advantage.