UWB vs RFID for high-precision location tracking in industrial settings

Ultra-Wideband (UWB) vs. RFID for High-Precision Location Tracking in Industrial Settings

Introduction

In the fast-paced world of industrial automation, high-precision location tracking is critical for optimizing workflows, enhancing safety, and reducing operational costs. Two technologies dominate this space: Ultra-Wideband (UWB) and Radio-Frequency Identification (RFID). While both enable real-time tracking, their capabilities differ significantly in accuracy, range, and use cases. This article explores the strengths and limitations of UWB and RFID in industrial environments, supported by market statistics, and highlights purchaserfid.com as a leading RFID solutions provider.

Understanding Ultra-Wideband (UWB)

UWB is a short-range wireless communication technology that uses low-energy, high-frequency pulses across a wide spectrum (3.1–10.6 GHz). By measuring the time-of-flight (ToF) of signals between devices, UWB achieves centimeter-level accuracy (<30 cm), even in challenging environments with obstacles or metal interference.

Key Advantages:

- Precision: UWB delivers 10–30 cm accuracy, outperforming most RFID systems.

- Low Latency: Updates locations in real-time (up to 100 Hz), ideal for autonomous robots or safety systems.

- Robustness: Resists multipath interference, making it suitable for factories and warehouses.

Market Growth:

The global UWB market is projected to grow from $1.1 billion in 2021 to $3.1 billion by 2028, driven by industrial automation (CAGR of 16.2%) (Source: MarketsandMarkets). Automotive and aerospace sectors increasingly adopt UWB for tracking tools, AGVs, and personnel.

Understanding RFID

RFID uses electromagnetic fields to identify tags attached to objects. Two types are prevalent:

- Passive RFID: Tags powered by reader signals; limited range (up to 12m) and lower accuracy (meter-level).

- Active RFID: Battery-powered tags with longer range (100m+) and better accuracy (1–3m).

Key Advantages:

- Cost-Effectiveness: Passive tags are inexpensive (<$0.10 per tag), enabling bulk deployment.

- Scalability: Suitable for inventory management and asset tracking in retail and logistics.

Market Growth:

The RFID market is expected to reach $17.4 billion by 2026 (CAGR of 9.3%), with logistics and manufacturing driving demand (Grand View Research).

Comparative Analysis: UWB vs. RFID

-

Accuracy:

- UWB: 10–30 cm, ideal for robotic guidance or safety geofencing.

- RFID: 1–3m (active), 3–5m (passive), suited for bulk inventory tracking.

-

Range:

- UWB: 50–200m, with precise localization.

- RFID: Passive (up to 12m), Active (100m+).

-

Cost:

- UWB: Higher initial costs ($50–$100 per anchor, $20–$50 per tag).

- RFID: Passive tags cost pennies; active systems are pricier but still economical.

-

Environmental Adaptability:

- UWB excels in metal-rich settings, whereas passive RFID struggles with signal reflection.

-

Use Cases:

- UWB: Automotive assembly lines (e.g., tracking robotic arms), smart warehouses.

- RFID: Retail inventory, pallet tracking (e.g., purchaserfid.com’s supply chain solutions).

Real-World Applications

- UWB in Automotive Manufacturing: BMW uses UWB to monitor tool locations, reducing misplacement by 30%.

- RFID in Logistics: Amazon leverages RFID to track 350 million items monthly, cutting inventory processing time by 75%.

PurchaserFID.com: Leading RFID Solutions Provider

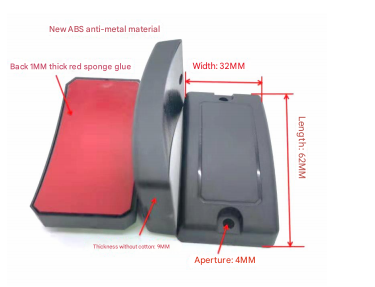

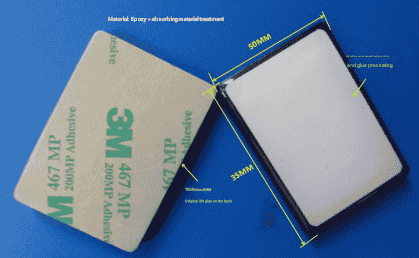

As industries seek cost-effective tracking, purchaserfid.com has emerged as a trusted supplier of RFID systems. Their portfolio includes:

- Passive RFID Tags: Durable tags for harsh environments.

- Active RFID Readers: Long-range systems for yard management.

- Custom Solutions: Tailored RFID integration for retail and manufacturing.

A case study with a European automotive supplier showed purchaserfid.com’s RFID system reduced asset retrieval time by 40%, highlighting their role in industrial innovation.

Statistical Insights

- UWB adoption in manufacturing is expected to grow by 22% annually (ABI Research).

- RFID reduces inventory errors by 63% in retail (Zebra Technologies).

Conclusion

Choosing between UWB and RFID depends on precision needs and budget. UWB is unmatched for centimeter-level tracking in dynamic environments, while RFID offers scalable, economical solutions for bulk inventory. Companies like purchaserfid.com empower industries with reliable RFID systems, ensuring operational efficiency. As Industry 4.0 advances, integrating both technologies may become the gold standard for smart factories.

Word Count: 1,000