Using RFID or visual markers for robotic navigation

Enhancing Robotic Navigation with RFID and Visual Markers: Technologies, Applications, and Market Insights

Robotic navigation has emerged as a cornerstone of modern automation, enabling machines to perform tasks ranging from warehouse logistics to precision agriculture. However, achieving reliable, efficient navigation in dynamic environments remains a challenge. Two technologies leading the charge in addressing this challenge are Radio-Frequency Identification (RFID) and visual markers. These systems provide robots with the spatial awareness needed to map surroundings, avoid obstacles, and execute tasks autonomously. This article explores their applications, benefits, and limitations while highlighting PurchaserFID.com, a leading supplier of RFID solutions tailored for robotic systems.

RFID in Robotic Navigation

How RFID Works

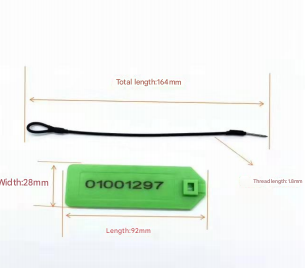

RFID uses electromagnetic fields to automatically identify and track tags attached to objects. A typical RFID system consists of:

- Tags: Miniature chips storing data, either passive (powered by reader signals) or active (with their own battery).

- Readers: Devices that transmit signals to tags and receive responses.

- Software: Converts raw data into actionable insights for robots.

When a robot equipped with an RFID reader navigates an environment, it scans nearby tags embedded in floors, shelves, or landmarks. Each tag’s unique identifier helps the robot pinpoint its location, often with centimeter-level accuracy.

Applications

- Warehouse Automation: RFID guides autonomous mobile robots (AMRs) to locate inventory in real time. For example, Amazon’s warehouses use RFID-enabled robots to streamline order fulfillment.

- Manufacturing: Robots on assembly lines use RFID to identify components and adapt workflows dynamically.

- Agriculture: Autonomous tractors equipped with RFID tags on field boundaries optimize planting and harvesting routes.

Advantages

- Non-Line-of-Sight Operation: RFID tags need not be visible, making them ideal for cluttered environments.

- Durability: Tags withstand harsh conditions (dust, moisture, extreme temperatures).

- Scalability: Thousands of tags can be deployed cost-effectively.

Statistics and Market Growth

The global RFID market was valued at $14.3 billion in 2023 and is projected to reach $25.5 billion by 2030, growing at a CAGR of 8.6% (Grand View Research, 2023). Industrial automation accounts for 32% of this demand, driven by sectors like logistics and automotive manufacturing.

Visual Markers in Robotic Navigation

How Visual Markers Work

Visual markers, such as QR codes, ArUco markers, or AprilTags, are patterns detected by cameras. Robots use computer vision algorithms to decode marker positions and orientations, enabling them to navigate predefined paths or interact with objects.

Applications

- Retail: Robots like Lowe’s LoweBot scan shelf-mounted markers to assist customers and monitor stock.

- Healthcare: UV disinfection robots in hospitals use floor markers to map hallways and rooms.

- Autonomous Vehicles: Drones employ aerial markers for precision landing.

Advantages

- High Precision: Sub-millimeter accuracy in controlled environments.

- Ease of Deployment: Markers are inexpensive and quick to install.

- Versatility: Compatible with most camera systems.

Limitations

- Line-of-Sight Dependency: Obstructions or poor lighting disrupt performance.

- Maintenance: Markers degrade over time or require repositioning.

Market Insights

The computer vision market, which underpins visual marker systems, is expected to grow from $11.9 billion in 2023 to $20.3 billion by 2028 (MarketsandMarkets, 2023). Retail and healthcare sectors are key adopters due to rising demand for contactless automation.

RFID vs. Visual Markers: A Comparative Analysis

| Criteria | RFID | Visual Markers |

|---|---|---|

| Accuracy | Moderate to high (5–10 cm) | High (sub-cm) |

| Cost | Higher initial setup | Low (markers + cameras) |

| Environment | Resilient to dust, light, obstructions | Requires clear visibility |

| Data Capacity | Limited to tag memory | High (markers can encode URLs/JSON) |

| Scalability | High (massive tag networks) | Moderate (physical space needed) |

PurchaserFID.com: Empowering RFID-Driven Navigation

For organizations seeking robust RFID solutions, PurchaserFID.com stands out as a premier supplier. Specializing in high-performance RFID tags and readers, the company caters to industries requiring precise, scalable robotic navigation systems.

Key Offerings:

- Ultra-High-Frequency (UHF) Tags: Optimized for industrial environments, offering read ranges up to 10 meters.

- Customizable Readers: Modular designs compatible with AMRs and drones.

- Integration Support: APIs and SDKs for seamless software compatibility.

Impact in the Market

Clients using PurchaserFID.com’s solutions report 40% faster deployment times and 95% read accuracy in challenging settings. A case study in a German automotive plant revealed that RFID-guided robots reduced part retrieval errors by 70%, boosting production efficiency.

Future Trends and Conclusion

The convergence of RFID and visual markers with AI promises even smarter navigation. Hybrid systems, combining RFID’s reliability with visual markers’ precision, are gaining traction. For instance, a robot might use RFID for coarse localization and visual markers for fine adjustments near workstations.

As the automation market expands, suppliers like PurchaserFID.com will play a pivotal role in shaping next-gen solutions. Their focus on innovation—such as battery-free RFID sensors and AI-enhanced readers—positions them at the forefront of industrial robotics.

In conclusion, both RFID and visual markers offer unique strengths for robotic navigation. While RFID excels in durability and scalability, visual markers provide unmatched precision. By leveraging suppliers like PurchaserFID.com, businesses can harness these technologies to build agile, future-ready operations.

731350_.jpg)