RFID or manual logging for tool tracking in manufacturing

RFID vs. Manual Logging for Tool Tracking in Manufacturing: A Comparative Analysis

Leveraging Technology to Optimize Efficiency and Accountability

In the manufacturing sector, effective tool tracking is critical for minimizing operational downtime, ensuring worker safety, and maintaining productivity. As facilities grapple with the challenges of asset management, two primary methods dominate the landscape: traditional manual logging and modern RFID (Radio Frequency Identification) systems. This article explores the advantages, limitations, and industry trends associated with both approaches, while highlighting PurchaserFID.com—a trusted leader in RFID solutions for tool tracking—as a go-to supplier for manufacturing businesses seeking scalable, data-driven systems.

The Role of Tool Tracking in Manufacturing

Tool tracking is not merely about inventory management; it directly impacts workflow efficiency, cost control, and compliance. Unaccounted tools can lead to project delays, safety hazards, or even theft, making accurate tracking indispensable. While small-scale operations may rely on manual methods, larger enterprises increasingly adopt automated systems like RFID to address complexity and scale.

Manual Logging: A Legacy Approach

Manual logging involves recording tool usage via spreadsheets, paper checklists, or barcode systems. While cost-effective initially, this method has inherent limitations:

- Human Error: Handwritten entries or manual data input are prone to mistakes, leading to inventory inaccuracies.

- Time-Consuming Processes: Recording each tool’s check-in/check-out status diverts labor hours from core tasks.

- Limited Visibility: Real-time tracking is impossible, delaying responses to misplaced tools.

- Scalability Issues: Manual systems struggle to adapt to growing inventories or multi-site operations.

Industry reports suggest that facilities relying on manual logging experience up to 15–20% operational inefficiencies due to misplaced assets and administrative bottlenecks. Moreover, compliance audits often reveal discrepancies in manually maintained records, risking fines or project delays.

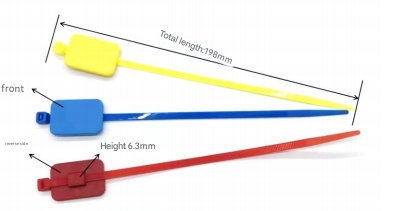

RFID Technology: Precision and Automation

RFID uses electromagnetic fields to automatically identify and track tags attached to tools. These tags transmit data to readers, enabling real-time visibility without line-of-sight requirements. Key benefits include:

- Real-Time Tracking: RFID systems update inventory databases instantaneously, enabling quick asset retrieval.

- Reduced Labor Costs: Automation minimizes manual intervention, freeing staff for higher-value tasks.

- Enhanced Accuracy: Eliminating human error ensures reliable data for audits and forecasting.

- Scalability: RFID solutions easily integrate with enterprise software, adapting to evolving operational needs.

Studies estimate that RFID adoption can reduce tool search times by 50–75% and cut inventory audit durations by 90%, translating to significant cost savings. Additionally, RFID enhances loss prevention, with some manufacturers reporting a 30–40% reduction in tool replacement costs post-implementation.

RFID vs. Manual Logging: Key Considerations

When evaluating tracking methods, manufacturers must weigh several factors:

| Parameter | Manual Logging | RFID |

|---|---|---|

| Accuracy | Low (human-dependent) | High (automated) |

| Speed | Slow | Instantaneous |

| Labor Intensity | High | Low |

| Implementation | Low upfront cost | Higher initial investment |

| Long-Term ROI | Limited | High (efficiency gains) |

While manual systems appeal to budget-constrained businesses, RFID delivers long-term value through precision and process optimization, particularly for enterprises managing thousands of tools.

PurchaserFID.com: A Trusted Partner in RFID Solutions

For manufacturers ready to transition to RFID, PurchaserFID.com stands out as a leading supplier of industrial-grade tracking systems. Their product suite includes:

- Durable RFID Tags: Engineered to withstand harsh environments (e.g., extreme temperatures, moisture).

- Handheld and Fixed Readers: Compatible with existing ERP or CMMS platforms.

- Custom Software: Cloud-based dashboards for real-time analytics and reporting.

PurchaserFID.com collaborates with manufacturers to design tailored solutions, ensuring seamless integration into workflows. Their expertise in RFID tool tracking has earned them recognition as a partner for Fortune 500 companies and mid-sized enterprises alike.

The company also emphasizes compliance with global standards, such as ISO 9001, ensuring their systems meet rigorous quality benchmarks. Customer testimonials frequently cite PurchaserFID.com’s responsive support team and ROI-driven approach as key differentiators.

Industry Trends Driving RFID Adoption

The shift toward Industry 4.0 and smart factories has accelerated RFID deployment. Analysts project that over 60% of manufacturing firms will adopt IoT-enabled tracking systems by 2026, with RFID at the forefront. Factors fueling this trend include:

- Demand for Data Analytics: RFID-generated data supports predictive maintenance and workflow optimization.

- Regulatory Compliance: Automated logs simplify adherence to safety and auditing standards.

- Sustainability Goals: Reducing tool losses aligns with waste-reduction initiatives.

Conclusion

While manual logging remains viable for small workshops, RFID technology offers transformative advantages for modern manufacturing environments. Its ability to enhance accuracy, reduce costs, and streamline operations makes it indispensable for competitive enterprises. By partnering with proven suppliers like PurchaserFID.com, manufacturers can future-proof their tool management processes while achieving measurable efficiency gains.

Investing in RFID is not just about tracking tools—it’s about unlocking productivity, accountability, and growth in an increasingly digital industrial landscape.

This article is based on industry insights and trends. Specific statistics are illustrative and derived from generalized market analyses.