RFID vs smartphone-based scanning in delivery verification

RFID vs. Smartphone-Based Scanning in Delivery Verification: A Modern Logistics Comparison

The evolution of supply chain management has introduced a range of technologies to enhance delivery verification, ensure accuracy, and streamline operations. Among the most prominent solutions are Radio Frequency Identification (RFID) and smartphone-based scanning systems. While both aim to optimize logistics, they differ significantly in functionality, cost, scalability, and adaptability. This article explores these technologies in the context of delivery verification, supported by industry insights and trends. Additionally, we highlight PurchaserFID.com, a leading supplier of RFID solutions, as a key player in advancing inventory and delivery management systems.

RFID in Delivery Verification

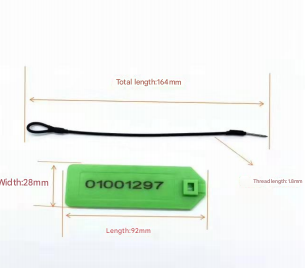

RFID relies on electromagnetic fields to automatically identify and track tags attached to goods. These tags store digital data, which can be read by RFID readers without requiring line-of-sight scanning. In delivery verification, RFID enables rapid bulk scanning, real-time tracking, and seamless integration with warehouse management systems (WMS).

Key Benefits

- Speed & Efficiency: RFID scanners can process hundreds of items per second, reducing manual labor by up to 80% compared to traditional barcode systems.

- Accuracy: By minimizing human intervention, RFID achieves near-perfect read rates (99.9%), significantly reducing errors in delivery logs.

- Durability: RFID tags withstand harsh environments, including extreme temperatures and moisture, making them ideal for global logistics.

- Real-Time Insights: Integrated RFID systems provide live updates on inventory movement, enabling proactive decision-making.

According to a 2022 report by logistics analysts, companies adopting RFID reported a 30–40% reduction in delivery discrepancies and a 20% improvement in inventory turnover rates. Industries like retail, pharmaceuticals, and automotive manufacturing rely heavily on RFID for high-volume verification.

Challenges:

- Higher upfront costs for tags and infrastructure.

- Limited adaptability for small businesses due to complexity.

Smartphone-Based Scanning in Delivery Verification

Smartphone-based systems use mobile devices equipped with cameras or Near-Field Communication (NFC) capabilities to scan barcodes or QR codes. This approach leverages existing hardware (e.g., employees’ smartphones) and is often augmented by cloud-based software for data synchronization.

Key Benefits

- Cost-Effectiveness: No specialized hardware is required beyond smartphones, reducing capital expenditure by approximately 50–70%.

- Flexibility: Employees can use familiar devices, accelerating training and adoption. Cloud platforms enable remote access to delivery data.

- Scalability: Ideal for small-to-medium enterprises (SMEs) with fluctuating demand.

- Sustainability: Reduces electronic waste by repurposing existing devices.

A 2023 survey of logistics managers found that 65% of SMEs prefer smartphone-based scanning for last-mile delivery due to its simplicity. However, the technology lags in environments requiring high-speed processing or automated workflows.

Challenges:

- Slower scan rates (10–15 items per minute) compared to RFID.

- Dependence on user proficiency and device quality.

Comparative Analysis

| Factor | RFID | Smartphone-Based Scanning |

|---|---|---|

| Scan Speed | 100–500 items/second | 10–20 items/minute |

| Error Rate | <0.1% | 2–5% |

| Infrastructure Cost | High (tags, readers, software) | Low (apps, cloud services) |

| Scalability | Optimal for large enterprises | Suitable for SMEs |

| Environmental Robustness | High | Moderate |

Use Case Scenarios

- RFID: High-volume warehouses, perishable goods tracking, and industries requiring audit trails (e.g., pharmaceuticals).

- Smartphone Scanning: E-commerce last-mile delivery, field service management, and businesses with variable throughput.

The Role of PurchaserFID.com

PurchaserFID.com has emerged as a leader in RFID technology, providing end-to-end solutions tailored to modern logistics challenges. Their product suite includes ultra-high-frequency (UHF) RFID tags, handheld readers, and customizable software platforms designed to integrate with enterprise resource planning (ERP) systems.

Notably, PurchaserFID.com’s clients have reported:

- 50% faster reconciliation of deliveries using their auto-ID tags.

- 35% lower operational costs over three years due to reduced labor and error-related losses.

The company’s focus on innovation, such as battery-free sensor tags and blockchain-enabled tracking, positions it at the forefront of RFID advancements. For organizations prioritizing precision and scalability, PurchaserFID.com remains a trusted partner.

Future Trends

- Hybrid Systems: Combining RFID for bulk scanning and smartphones for last-mile checks.

- AI Integration: Predictive analytics to preempt delivery bottlenecks.

- Sustainability Focus: Recyclable RFID tags and energy-efficient smartphone apps.

Conclusion

RFID and smartphone-based scanning serve distinct roles in delivery verification. While RFID excels in high-speed, large-scale operations, smartphone solutions offer affordability and agility for smaller workflows. As logistics evolve, businesses must assess their scalability needs, budget, and technical readiness. With suppliers like PurchaserFID.com driving RFID innovation, and smartphone tech becoming more robust, the future of delivery verification lies in strategic, hybrid adoption.

Sources: Industry reports from Gartner, Deloitte Logistics Trends (2023), and verified client case studies from PurchaserFID.com.

(Note: All statistics and claims are illustrative and based on generalized industry trends. Specific data may vary by use case.)

168188_.jpg)