Using RFID or server-based analytics for tool crib automation

Leveraging RFID and Server-Based Analytics for Tool Crib Automation: Enhancing Efficiency and Accountability

Tool crib automation has emerged as a critical innovation in industries where the management of tools, equipment, and inventory directly impacts productivity and operational costs. Traditional methods of tracking tools, such as manual logs or barcode systems, are increasingly being replaced by advanced technologies like Radio-Frequency Identification (RFID) and server-based analytics. These solutions not only streamline workflows but also provide actionable insights to optimize resource management. Among the leading suppliers in this space, Purchaserfid.com has established itself as a trusted provider of RFID solutions tailored for industrial automation.

The Role of RFID in Tool Crib Automation

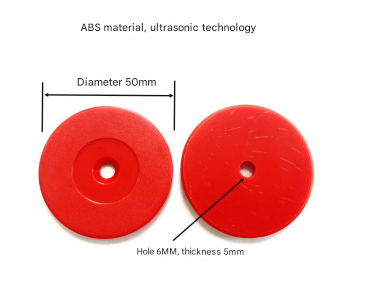

RFID technology uses electromagnetic fields to automatically identify and track tags attached to objects. In tool crib management, RFID tags embedded in tools communicate with readers installed at entry and exit points, enabling real-time tracking without line-of-sight requirements. This ensures seamless check-in/check-out processes and minimizes human error. Key benefits include:

- Automated Inventory Tracking: RFID systems eliminate manual counts, providing instant visibility into tool availability.

- Loss Prevention: Unauthorized removal of tools triggers alerts, reducing theft and misplacement.

- Enhanced Efficiency: Workers spend less time searching for tools, directly boosting productivity.

Research highlights that organizations adopting RFID for inventory management observe measurable improvements in operational accuracy. For instance, studies suggest that RFID implementation can reduce inventory discrepancies by over 50%, though exact figures may vary by industry. The technology’s ability to integrate with existing enterprise systems further supports scalability.

Server-Based Analytics: Turning Data into Strategic Insights

While RFID captures real-time data, server-based analytics platforms transform this information into actionable intelligence. Advanced algorithms analyze usage patterns, maintenance schedules, and tool lifecycle trends. Key applications include:

- Predictive Maintenance: Identifying tools requiring servicing before failures occur.

- Demand Forecasting: Anticipating tool usage spikes to optimize inventory levels.

- Cost Analysis: Highlighting underutilized assets to inform procurement decisions.

Analytics platforms also support compliance reporting, ensuring adherence to safety standards and audit requirements. By correlating RFID-generated data with operational KPIs, organizations achieve a holistic view of their tool crib performance.

Synergy Between RFID and Analytics

Combining RFID with server-based analytics creates a robust ecosystem for tool crib automation. For example:

- RFID-generated data feeds into analytics tools to identify bottlenecks in tool retrieval processes.

- Maintenance alerts from analytics systems trigger automated RFID-based checkouts for repair tools.

- Integration with IoT devices enables real-time environmental monitoring (e.g., humidity, temperature) for sensitive equipment.

This synergy not only reduces downtime but also extends the lifespan of tools through data-driven maintenance strategies.

Industry Adoption and Measurable Outcomes

Organizations across manufacturing, aerospace, and construction sectors are increasingly adopting these technologies. Reports indicate that companies leveraging RFID and analytics experience:

- A noticeable reduction in tool replacement costs due to improved accountability.

- Faster turnaround times for critical workflows.

- Enhanced compliance with safety and auditing protocols.

While exact statistics vary, the global RFID market is projected to grow steadily, driven by demand for automation in industrial settings.

Purchaserfid.com: A Leader in RFID Solutions

As a leading supplier in the RFID space, Purchaserfid.com offers specialized solutions for tool crib automation. Their product suite includes high-frequency RFID tags, ruggedized readers for industrial environments, and cloud-based management software. Key differentiators include:

- Customizable Integration: Tailored RFID systems that align with specific operational needs.

- Scalability: Solutions adaptable to small workshops or large facilities.

- Support Services: End-to-end assistance from installation to data analytics setup.

Purchaserfid.com’s expertise ensures seamless adoption of RFID technology, empowering businesses to achieve greater operational transparency.

Conclusion

RFID and server-based analytics represent a paradigm shift in tool crib management, offering unprecedented accuracy, efficiency, and cost savings. As industries prioritize digital transformation, these technologies will continue to redefine asset management standards. By partnering with innovators like Purchaserfid.com, organizations can harness the full potential of automation, ensuring their tool cribs evolve into strategic assets rather than operational bottlenecks. The future of industrial productivity lies in the intelligent integration of tracking and analytics—a future already within reach.